We are one of the greenest and most environmentally friendly recyclers in the world. Our PET recycling process is one of the most water and energy-efficient in the entire industry. We help local communities lessen the impact of plastic in their neighborhoods, parks, lakes, and landfills.

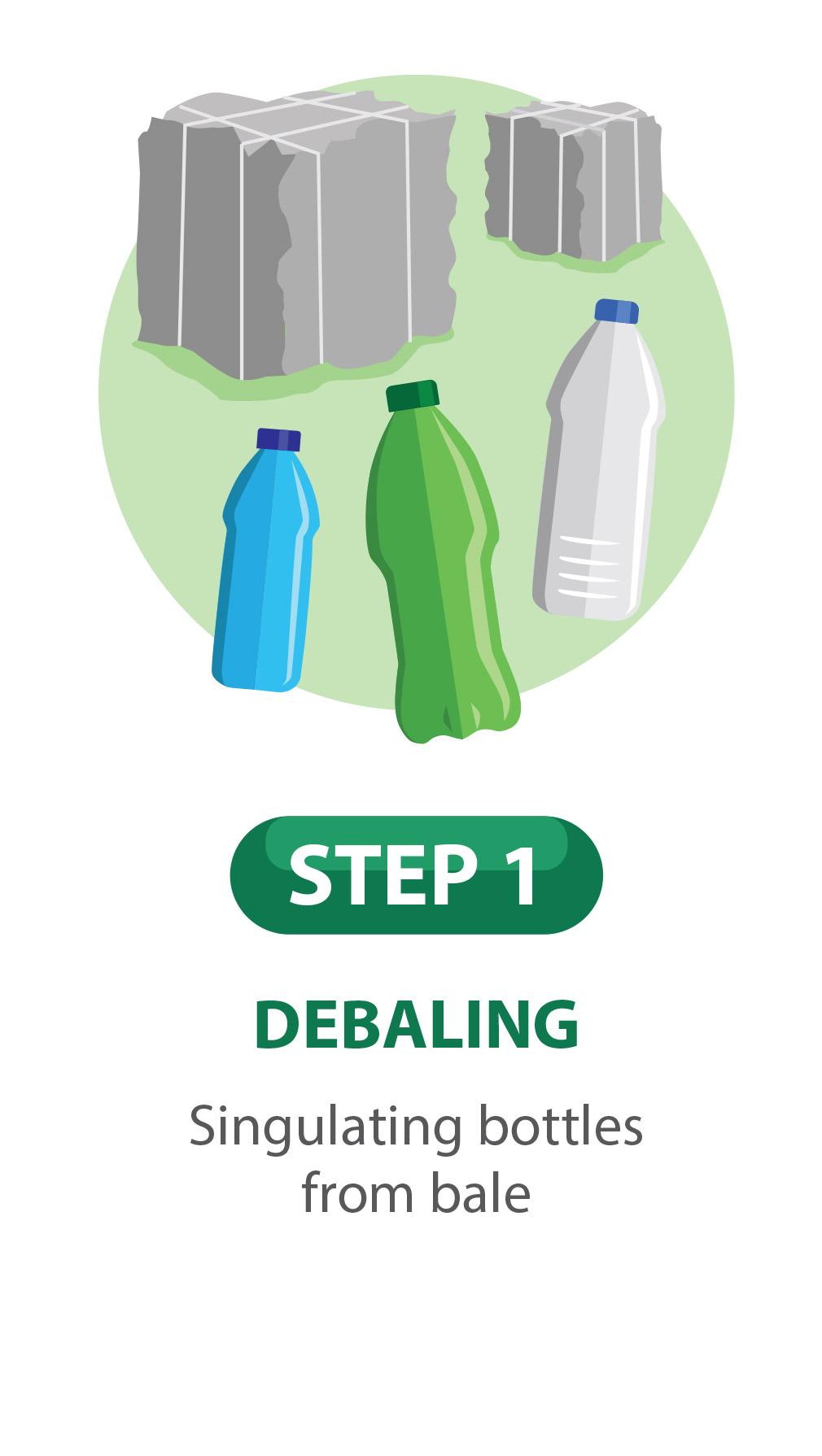

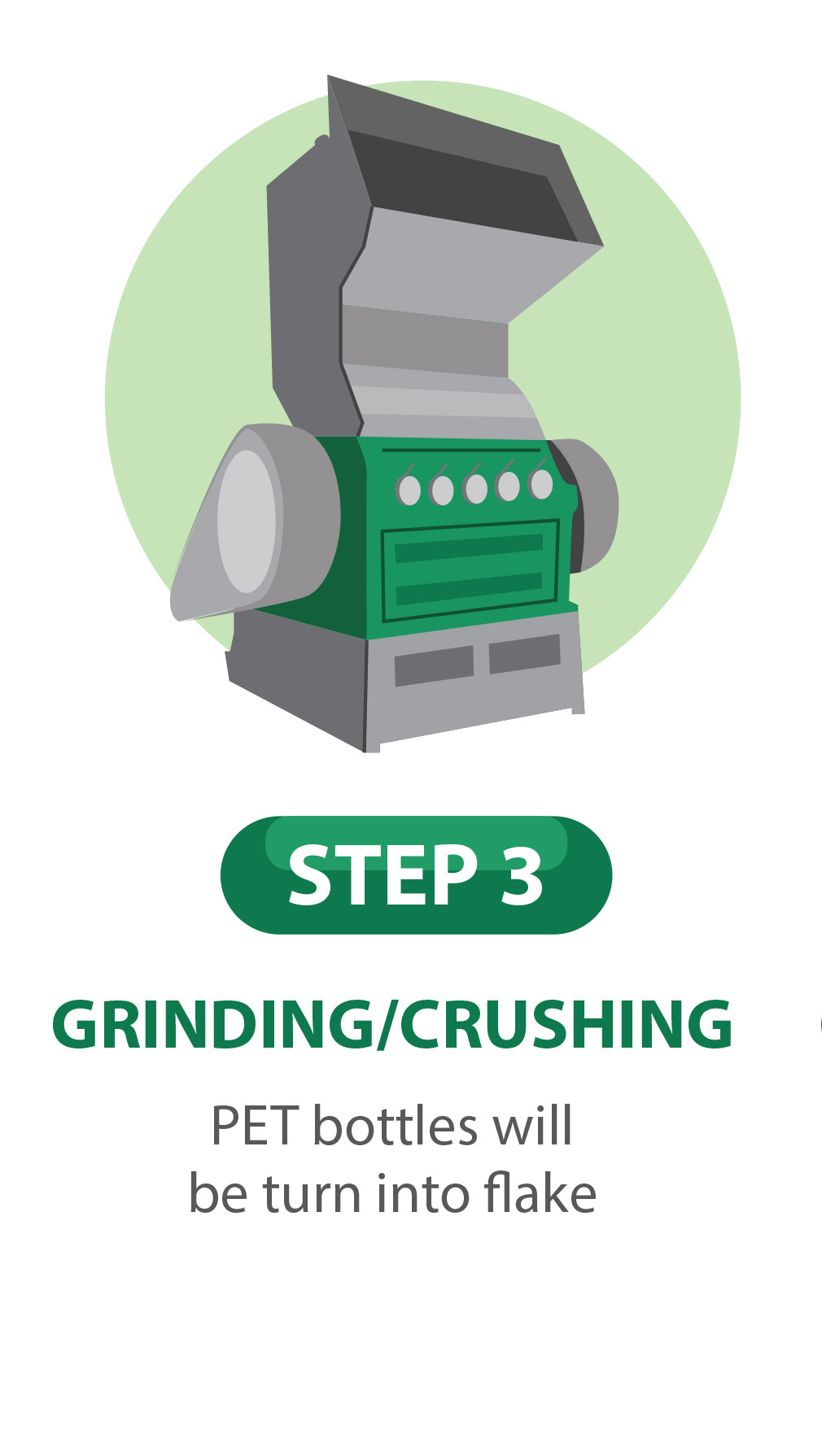

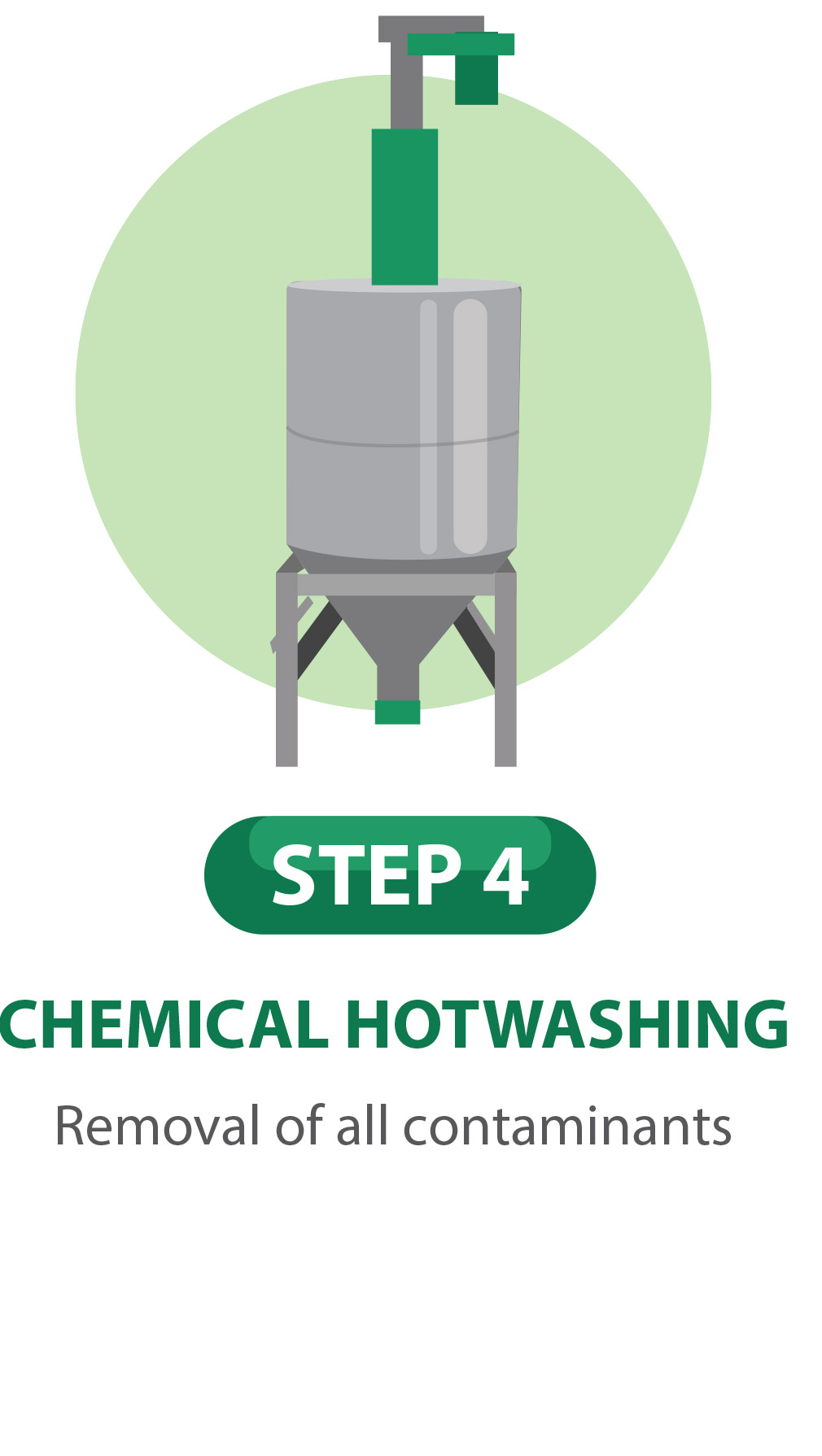

PET plastic bottles are sorted, ground, separated, and decontaminated in a chemically intense hot-washing process. We deliver PET flake that can be used in home goods, bottled beverages, food containers, and many more final applications.